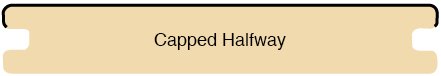

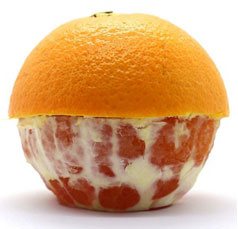

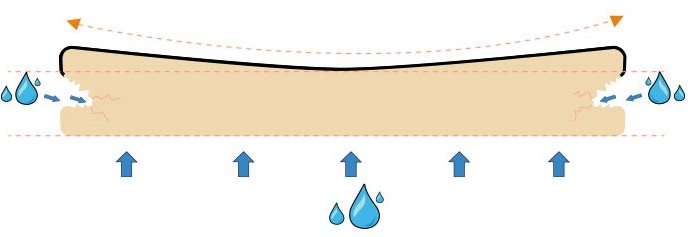

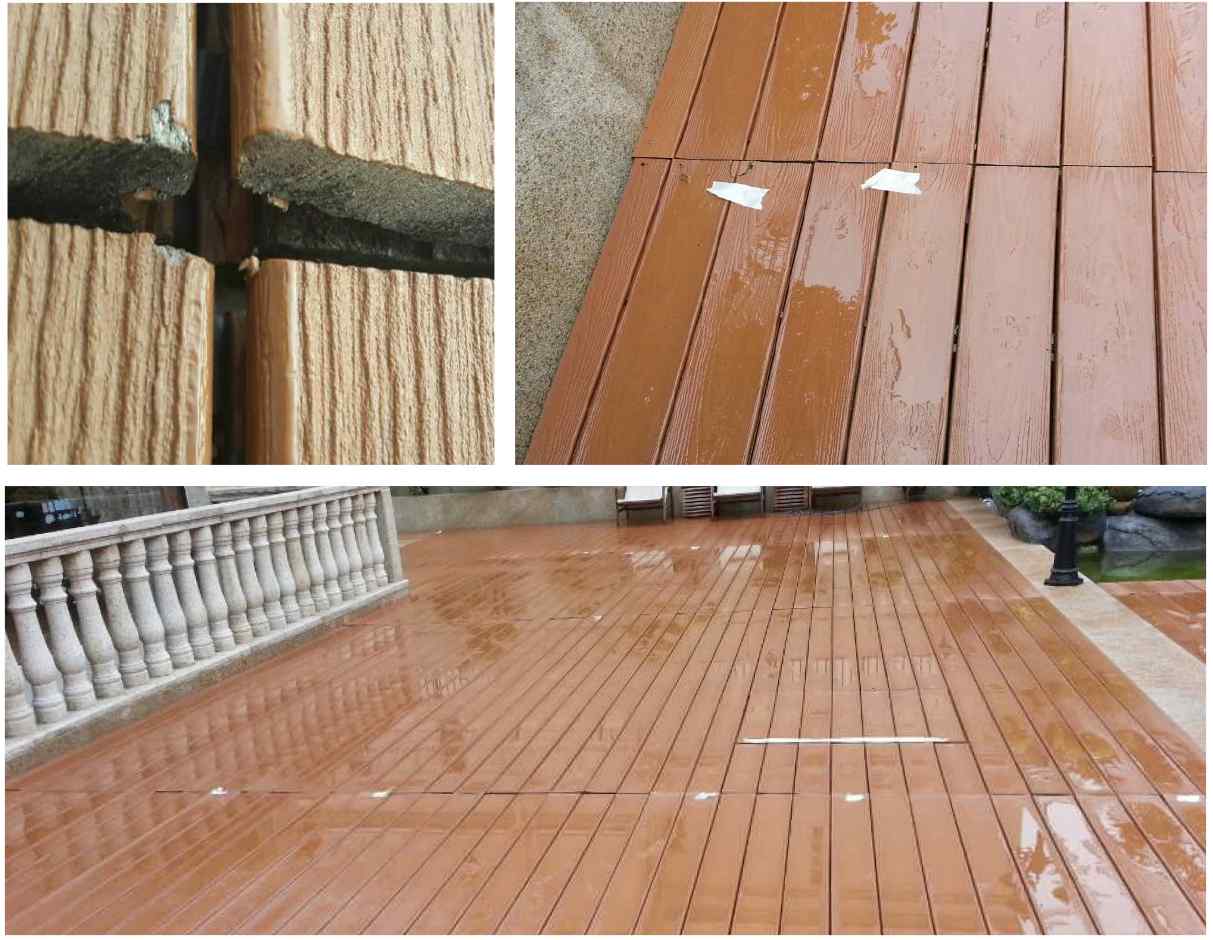

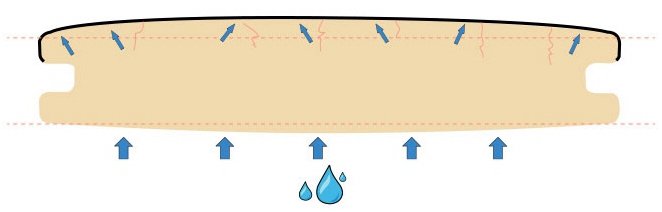

Some capped composite wood is only half capped, this solves some problems, but other problems occur. Capping the top half of the board does provide higher stain, scratch, and UV resistance, however, the underside and grooves of the board are exposed to the elements and that creates dry and wet effect on the top and bottom.